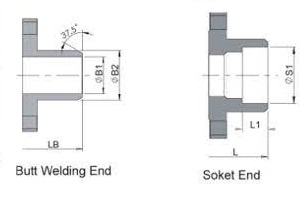

Socket welding is to insert one end of the pipe into the object to be welded with it, which is good for positioning, good welding and high strength. Socket welds are fillet welds, and socket welds have a higher pressure resistance and are commonly used for high-voltage parts. Socket welding is that the pipe is inserted into the tube sheet, and its weld is called a fillet joint. Socket welding is that the pipe is inserted into the flange or the inside of the pipe fitting, and a fillet weld is welded at the interface. The flange or fitting interface is larger than the pipe and has a cap to allow the pipe to be inserted.

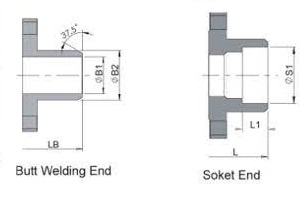

Butt welding is to weld the end faces of two objects together, which is not easy to align, and the welding strength is relatively low. Butt welding is a flat weld, butt welding is generally suitable for low-pressure pipelines, and low-pressure valves are commonly used. The butt welded pipe is a convex pipe. Butt welding is a butt joint, butt welding, the pipe is as large as the flange or pipe joint, and the interface is butted, that is flat. Socket welding has a socket and a spigot, which is the cooperation between the section and the pipe; while the butt welding is a section-to-section.

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.