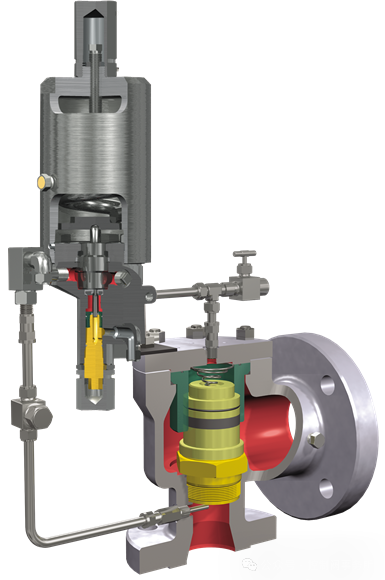

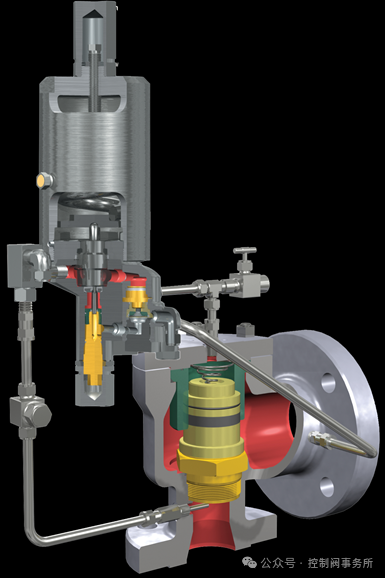

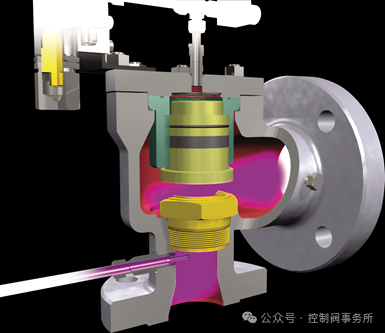

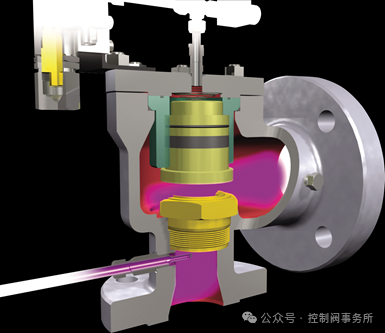

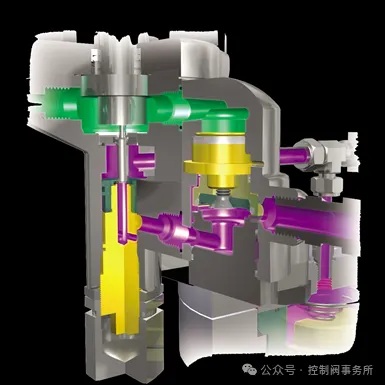

A pilot-operated safety relief valve is a pressure control device in which the main relief component (main valve) is used in conjunction with a self-operated auxiliary pressure control device called a pilot valve, which controls the opening and closing of the main valve. Pilot-operated safety relief valves can be fast-acting or regulating, corresponding to pop-up pilot valves and regulating pilot valves, respectively. Figures 1 and 2 below show schematic diagrams of these two types of pilot valves.

Figure 1: Quick-acting pilot-operated safety relief valve (POP Action POSRV)

Figure 2: Modulating Action POSRV

Basic Operating Principles of Pilot-Operated Safety Relief Valves

The pilot valve is operated by system pressure, which controls the closing force of the main valve disc. As inlet pressure increases, the closing force increases until the pilot valve opens, allowing the process media to discharge through the main valve, thereby relieving pressure at the set point.

Fast-Acting Pilot Valves

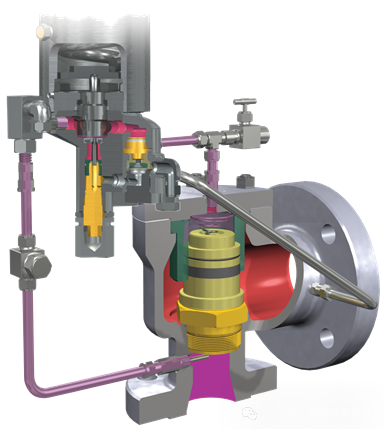

The main valve disc with a fast-acting pilot configuration will "pop" from the seated position to a 100% open state. When the overpressure condition is relieved, the main valve disc will re-seat due to the increase in media pressure directed through the pilot valve, as shown in Figure 3. System pressure at the main valve inlet is transmitted by the pilot valve through the interconnecting pipework to the dome area, causing the pressure on the top of the disc to equal the inlet pressure at the seat. Because the area of the top of the disc is larger than the area of the seat, the net downward force generated by this area difference keeps the main valve closed.

Figure 3: Main valve closed (normal position)

Figure 4 shows that as the inlet pressure increases, the pilot piston moves and cuts off the connection between the main valve inlet pressure and the dome pressure. At the same time, the pilot piston opens the exhaust seal and releases the dome pressure to the atmosphere.

Figure 4: Pilot valve open (relief position)

When the fluid force overcomes the pressure load above the main valve disc, the main valve disc lifts from the valve seat and the valve begins to discharge to relieve system pressure, as shown in Figure 5.

Modulating Pilot Valves

The modulating pilot valve operates similarly to the snap-acting type, but with the added ability to maintain a percentage of system pressure above the main valve disc, creating a modulating effect. As system pressure increases, the pilot valve vents causing the closing force to decrease. Pressure begins to release at the set point as the process media exhausts through the main valve. However, the actual degree of opening of the main valve disc is determined by the specific system overpressure condition, rather than an instantaneous "bounce" to the 100% open position. This "modulating" action reduces media loss and emissions, improving operating efficiency.

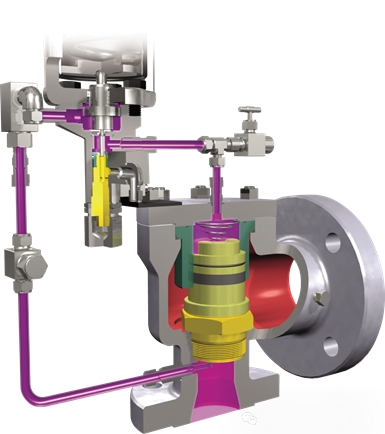

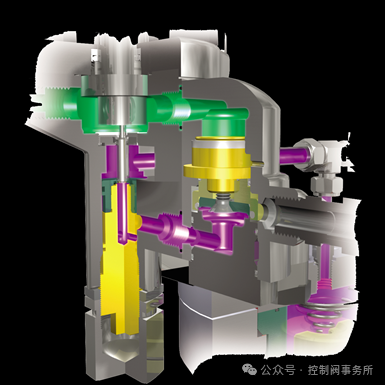

Figure 6 illustrates how system pressure at the main valve inlet is delivered to the dome area by the pilot through interconnecting piping. This equalizes the pressure at the top of the disc with the inlet pressure at the disc seating surface (bottom). Because the area of the disc top is larger than the area of the seat surface, the area difference creates a net downward force that keeps the main valve tightly closed.

Figure 6: Main Valve Closed (Normal Position)

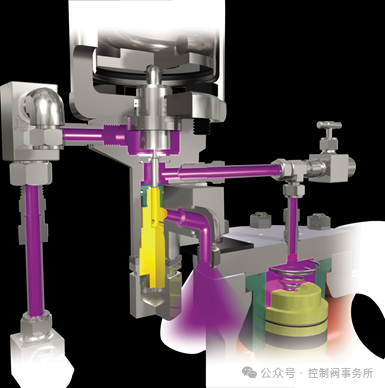

Figure 7 shows that as inlet pressure increases, the pilot piston strokes and isolates the main valve inlet pressure from the dome pressure. The pilot piston simultaneously opens the exhaust seal, relieving the dome pressure to the bottom of the modulator piston. The modulator piston has a differential area, with the smaller area at the top. This piston top is always subject to the main valve inlet pressure.

When the dome pressure acts on the bottom of the modulator piston, a net upward force is created. This is because the two pressures are equal (at this point) and the lower area is greater than the upper area. The modulator relieves the pressure in the dome to atmosphere until the inlet pressure at the top of the modulator piston is sufficient to move it to the closed position. There is still some pressure in the dome. This pressure is controlled by the differential pressure in the modulator. Because the dome pressure has not yet dropped to atmospheric pressure, the main valve is only partially open at the set point.

The modulator piston will remain closed until the main valve disc is forced up by the increased inlet pressure. During this process, the modulator piston can relieve the dome pressure further as needed to achieve the desired main valve disc lift within the 10% overpressure range.

Figure 7: Adjustment position

As the inlet pressure increases further, the net lift on the main valve also increases, causing the main valve to release more pressure until the valve disc achieves full lift within 10% of the set pressure, as shown in Figure 8.

Figure 8: Main valve fully open

When the exhaust pressure drops to the pilot preset exhaust pressure, the pilot piston closes the exhaust seal. At the same time, the pilot valve inlet seal reopens and the main valve inlet pressure again enters the main valve dome. When the dome pressure equals the inlet pressure, the resulting downward force closes the main valve.

Advantages of pilot-operated SRVs over spring-loaded SRVs

Pilot-operated SRVs have several advantages over spring-loaded SRVs:

—Pilot-operated SRVs provide a seat tightness of 98% for both the main and pilot valves to the set pressure. This ensures zero leakage under normal operating conditions, even in the most demanding high-pressure applications.

—The pilot-operated SRV has a higher seat force than the spring-loaded SRV, making it an ideal solution for higher working pressure clearances. Operating closer to the maximum allowable working pressure (MAWP) helps keep the system operating at optimal conditions.

—Full-bore pilot-operated SRVs have a larger capacity than standard-bore SRVs of comparable valve size. This unique product allows operators to save on valve costs and associated piping investments due to reduced pipe diameter.

—The pilot operated regulating valve can be adjusted based on the flow required for an overpressure event rather than the rated flow of the valve. This allows users to use the system required flow rather than the valve rated flow when calculating line losses, thereby reducing inlet line losses.

—The field test connection allows operators to functionally test the pilot operated SRV while it is still in use and continues to protect the system from unexpected overpressure events.

—The dual pilot option allows users to reduce unplanned downtime by repairing or replacing one offline pilot while the other pilot continues to protect the system. This allows service technicians to perform scheduled service and repairs.

—The unique design of the pilot operated SRV connects it to the main valve through interconnecting pipes, allowing different accessories to be installed. This includes manual blowdown valves, filters, backflow preventers, differential pressure switches, pilot valve testers, remote pilot installation, dome auxiliary pilots, etc.

Limitations of Pilot-Operated SRVs

As we have seen, pilot-operated SRVs have some advantages over spring-operated SRVs, but there are also some limitations to consider. Depending on the severity of the dirty service, filters of different types and capacities can be installed, as well as dome assist options to isolate the dirty process media from critical valve components such as the modulator, dome assembly, vent, and inlet seal.

However, for severely dirty services that could plug the interconnecting piping, a pilot-operated SRV may not be the most appropriate choice. Pilot-operated SRVs work by allowing system pressure from the main valve inlet time to fill the dome area through the interconnecting piping. During equipment startup, when the ramp rate of system pressure is extremely rapid, the dome area may not equalize with the same inlet pressure, resulting in insufficient closing force.

Therefore, system pressure from the main valve inlet will push the main valve disc up and begin to leak. A spring or alternative pressure can be added to the main valve dome area to close the main valve disc while allowing time for the system pressure to rise. If these remedies are not feasible or economical, a spring-loaded SRV would be a better choice in applications where the pressure slope is too high.

Common Industries and Applications

Like spring-loaded SRVs, pilot-operated SRVs are used in many industries. Common industries that use these valves include power generation, refining/petrochemical, chemical, midstream oil and gas, upstream oil and gas, and pulp and paper. Some unique applications for pilot-operated SRVs include high-pressure applications, reducing emissions in high-working pressure applications, offshore drilling, production platforms in deep well applications, and any air/gas, liquid, steam, two-phase or multi-phase application.

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.