-

The difference between the ''Cartridge Sea'' and ''Booted Sea'' of Butterfly Valve

"Cartridge" suppllies more reliable torque, increased wear resistance, robustness and versatility than "Booted" … -

Difference Between Soft and Hard Back Seat Butterfly Valve

"Hard back Seat" as an economic choice if the valve size is less than DN500… -

Working principle and characteristics of flanged three-way ball valve

The flanged three-way ball valve is a three-channel rotary ball valve. The valve core of the flanged three-way ball valve has L type and T type, which can meet different production process requirements.… -

The advantages and connection form of forged steel globe valve

The pressure self-tightening bonnet forged steel globe valve. The valve designed according to this connection form, the valve body and the bonnet are connected by screw mosquitoes, and the internal pressure is sealed by the self-sealing ring. … -

Working principle of electric butterfly valve

Electric butterfly valve is a kind of electric valve and electric regulating valve.… -

The difference between electric gate valve and electric globe valve

The electric valve simply uses the electric actuator to control the valve, so as to realize the opening and closing of the valve.… -

Structural characteristics and classification of electric gate valve

Electric gate valve consists of stem, valve body, bonnet, gate, drive and other parts (fasteners, stem nut, sealing packing). Rod (torsion shaft), gate valve is thus divided into two types: open rod gate valve and dark rod gate valve.… -

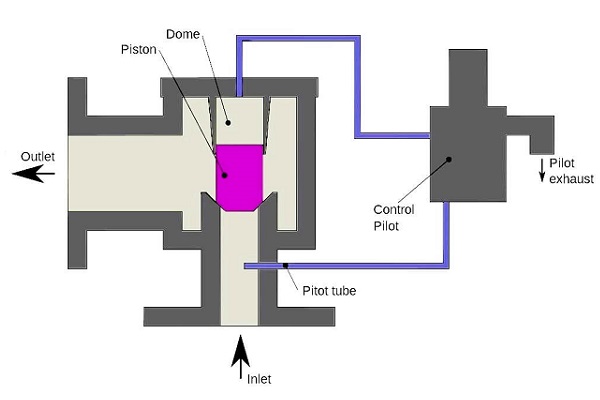

Classification and characteristics of pilot-operated safety valves

Pilot-operated safety valve (also known as pulse-type safety valve) is a safety valve that relies on the discharge of medium from the pilot valve to drive or control the main valve.…

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.