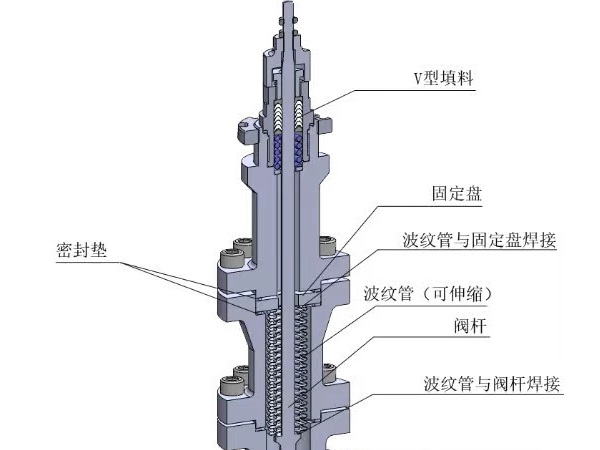

As the core and key component of the valve, the bellows is firmly connected to the valve stem by welding at its lower end, and can stably expand and contract with the rise and fall of the valve stem, thereby maintaining the tightness of the seal. This ingenious design greatly improves the reliability and safety of the valve under harsh working conditions such as flammable, explosive and toxic media. It can be said that the bellows-sealed valve structure plays an irreplaceable role in the above special working conditions and is an important equipment to ensure production safety and avoid environmental pollution. The typical bellows seal packing structure is shown in the figure below.

The working principle of the bellows can be clearly understood from the structural diagram: the valve stem runs through the bellows, the lower end of the bellows is welded to the valve stem, and the upper end is welded to the fixed plate. A through hole slightly larger than the diameter of the valve stem is set in the center of the fixed plate. During the valve installation process, the sealing gaskets need to be accurately installed on both sides of the fixed plate. With the help of the close cooperation of the valve cover and the bolts, the sealing gaskets are compacted to form a reliable sealing barrier, which completely isolates the medium from the external environment of the valve and effectively prevents the leakage of the medium.

The bellows has good elasticity. When the valve stem moves up and down, the lower end of the bellows will move smoothly, which not only ensures the normal operation of the valve, but also achieves a zero leakage sealing effect. In addition, in order to further improve the reliability of the valve and effectively prevent the bellows from being damaged due to long-term use, frequent force or pressure overload, resulting in medium leakage, a V-type packing is additionally configured on the upper part of the valve stem. This design is like adding a "double insurance" to the sealing performance of the valve. Even if the bellows is abnormal, the V-type packing can play a role in time, providing continuous and effective protection for the sealing of the valve. This multiple-security design concept enables bellows-sealed valves to perform more stably and reliably when dealing with complex and harsh working conditions, providing solid support for the safety and stability of industrial production.

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.